The Endless Referral System: cultivating new prospects and referrals (pt.3)

In part two of this series, we discussed meeting with new prospects to build referrals. But how do we go about looking for those referrals?

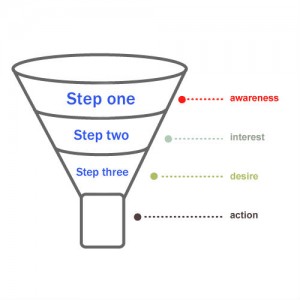

As mentioned before, it’s important not to come off as desperate. It takes time for prospects to get to know you and be comfortable with you. According to Bob, you can sense if people like you and it’s possible that you may not get that delightful feeling for a while. He describes the relationship building as a funnel.

The AIDA (Awareness, Interest, Desire, Action) funnel acts as good representation for this scenario. The first step, of course, is to get the prospect to acknowledge you (i.e. Hello, my name is…). The second step is to get their interest by making conversation, which we mentioned in part one. The third step is to create ‘desire’ in to do business with you or help you in some fashion, which I touched lightly on and will now expand.

The AIDA (Awareness, Interest, Desire, Action) funnel acts as good representation for this scenario. The first step, of course, is to get the prospect to acknowledge you (i.e. Hello, my name is…). The second step is to get their interest by making conversation, which we mentioned in part one. The third step is to create ‘desire’ in to do business with you or help you in some fashion, which I touched lightly on and will now expand.

After a few lunch meetings and some generous phone calls, lets say you and your prospect have bonded. It is now time to ask for a referral. Whether you meet with them in person or call them, here’s how you could “pop the question”:

“[Name], I’m in the process of expanding my business/referrals. I find it helpful to partner with colleagues, such as yourself. Can we take a few minutes to run past names of people I might be able to help?”

It is likely that if your prospect knows you, likes you, trusts you and wants to see you succeed. If this happens, then you have yourself a “walking ambassador” for you and your business. Note, initially this may be an overwhelming process for them, so be sure to help “funnel down their world” to narrow down their group of people to ask. You can frame your questions by creating visuals for your colleague. For example, have them think about who they socialize with, play golf or associations they participate in such as Rotary, professional groups or even their children’s’ activities. Your newly acquired prospects are absolutely important during this stage, so be sure to guide them into finding potential referrals. They don’t have to do this favor for you though, so remember to always give them an out. You can always preface, “John, as long as you are comfortable, can we run through a few groups that you are involved in?” A variation of this approach that we at Felber PR & Marketing have found helpful is to create lists of companies you would like an introduction.

Once they trust and like you, you can provide a short list of companies in your target market. This works especially well, since the company names trigger your colleague’s memory on who they may know at that company. Simply providing a “type of company” without a specific name often draws a blank. How many people can come up with names of contacts when you say “know anyone at a 10-100 million dollar, privately held business-to-business manufacturer?” We know, sounds precise, but it just does not generate referrals.

After you and your partner have finished the list, it is then time to contact these potential clients and/or new set of influencers! So in the next section, I will explain how to effectively communicate with this new group by emphasizing what value you can provide for to them.